伟德app安卓版下载安装教程是一家以工業(ye) 機器人以及自動化非標設備於(yu) 一體(ti) 的技術企業(ye) ,公司致力於(yu) 焊接、切割、機器人機床上下料等領域的機器人智能化研究和產(chan) 業(ye) 化應用

公司立足於(yu) 高端裝備製造等戰略新興(xing) 產(chan) 業(ye) ,將追逐“製造2025"致力於(yu) 機器人技術和互聯網技術的深度融合,推動智造。

發布:2024-03-27 瀏覽:0

1、提高了生產(chan) 效率。手工焊在對不鏽鋼製品的焊接中會(hui) 隨著工人的工作時間造成焊接效率低下,不鏽鋼伟德软件官方网站可以實現焊接過程自動化連續工作,重複動作不會(hui) 受到時間和環境等因素的影響,提高了焊接效率。

1. Improved production efficiency. Manual welding in the welding of stainless steel products can lead to low welding efficiency with the working time of workers. Stainless steel welding robots can achieve automatic and continuous welding process, and repetitive actions are not affected by factors such as time and environment, improving welding efficiency.

2、減少了企業(ye) 的成本支出。焊接市場中的不鏽鋼伟德软件官方网站的價(jia) 格在幾萬(wan) 到十幾萬(wan) 不等,相當於(yu) 一名普通焊接工人的年工資,不鏽鋼伟德软件官方网站的使用壽命長達數十年,給用戶帶來的生產(chan) 效益較高。

2. Reduced the cost expenditure of the enterprise. The price of stainless steel welding robots in the welding market ranges from tens of thousands to hundreds of thousands, which is equivalent to the annual salary of an ordinary welding worker. The service life of stainless steel welding robots can reach several decades, bringing high production efficiency to users.

3、解放了工人的勞動強度。傳(chuan) 統焊接中,工人會(hui) 直接接觸有害氣體(ti) 、激光、焊接煙塵、磁場等,對人體(ti) 造成危害,不鏽鋼伟德软件官方网站可實現焊接過程自動化,人工遠離焊接範圍,減少了職業(ye) 病的發生率。

3. Liberated the labor intensity of workers. In traditional welding, workers are directly exposed to harmful gases, lasers, welding fumes, magnetic fields, etc., which pose a threat to human health. Stainless steel welding robots can automate the welding process, keeping manual labor away from the welding range and reducing the incidence of occupational diseases.

4、重複定位精度穩定。不鏽鋼伟德软件官方网站根據型號不同,重複定位精度都維持在0.1mm以下,焊點在重複動作中也不會(hui) 發生偏移,焊接精度高,對焊縫焊接精準。

4. Stable repetitive positioning accuracy. The stainless steel welding robot maintains a repeated positioning accuracy of less than 0.1mm according to different models, and the welding points do not deviate during repeated actions, resulting in high welding accuracy and precise welding of the weld seam.

5、提供了較多的工作崗位。不鏽鋼伟德软件官方网站的生產(chan) 、安裝、調試、操作、維護保養(yang) 都需要工人進行,未來的焊接市場自動化和智能化水平會(hui) 不斷發展,實現自動化就業(ye) 不僅(jin) 會(hui) 提升自身技能,還會(hui) 使薪資水平提高一大步。

5. Provides a wide range of job positions. The production, installation, debugging, operation, and maintenance of stainless steel welding robots all require workers to carry out. The automation and intelligence level of the welding market will continue to develop in the future. Achieving automation employment will not only improve one's own skills, but also significantly increase salary levels.

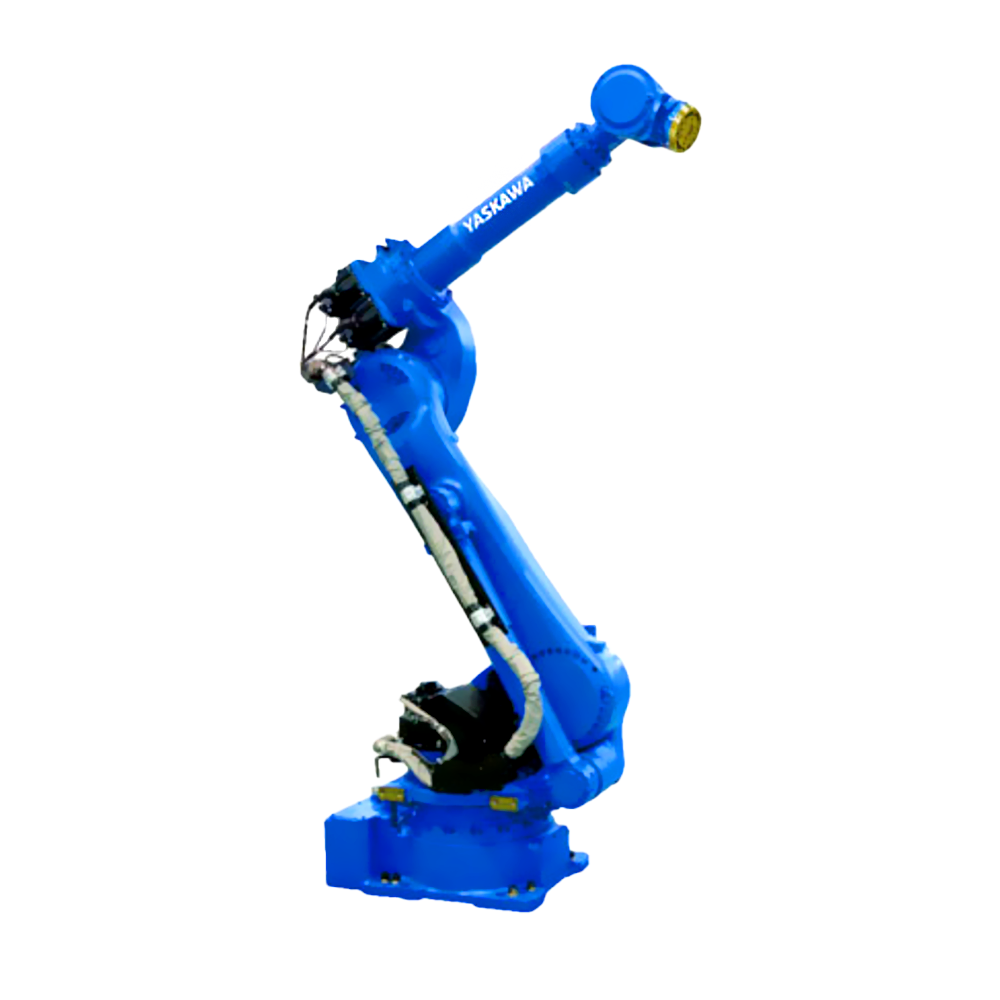

本文由安川機器人提供技術支持,更多的詳細精彩內(nei) 容請點擊我們(men) 的網站https://www.wobeier.com,我們(men) 將會(hui) 全心全意為(wei) 您提供滿意的服務。

This article is supported by Yaskawa Robotics. For more detailed and exciting content, please click on our website https://www.wobeier.com We will wholeheartedly provide you with satisfactory service.

產(chan) 品分類

新聞

截屏,微信識別二維碼